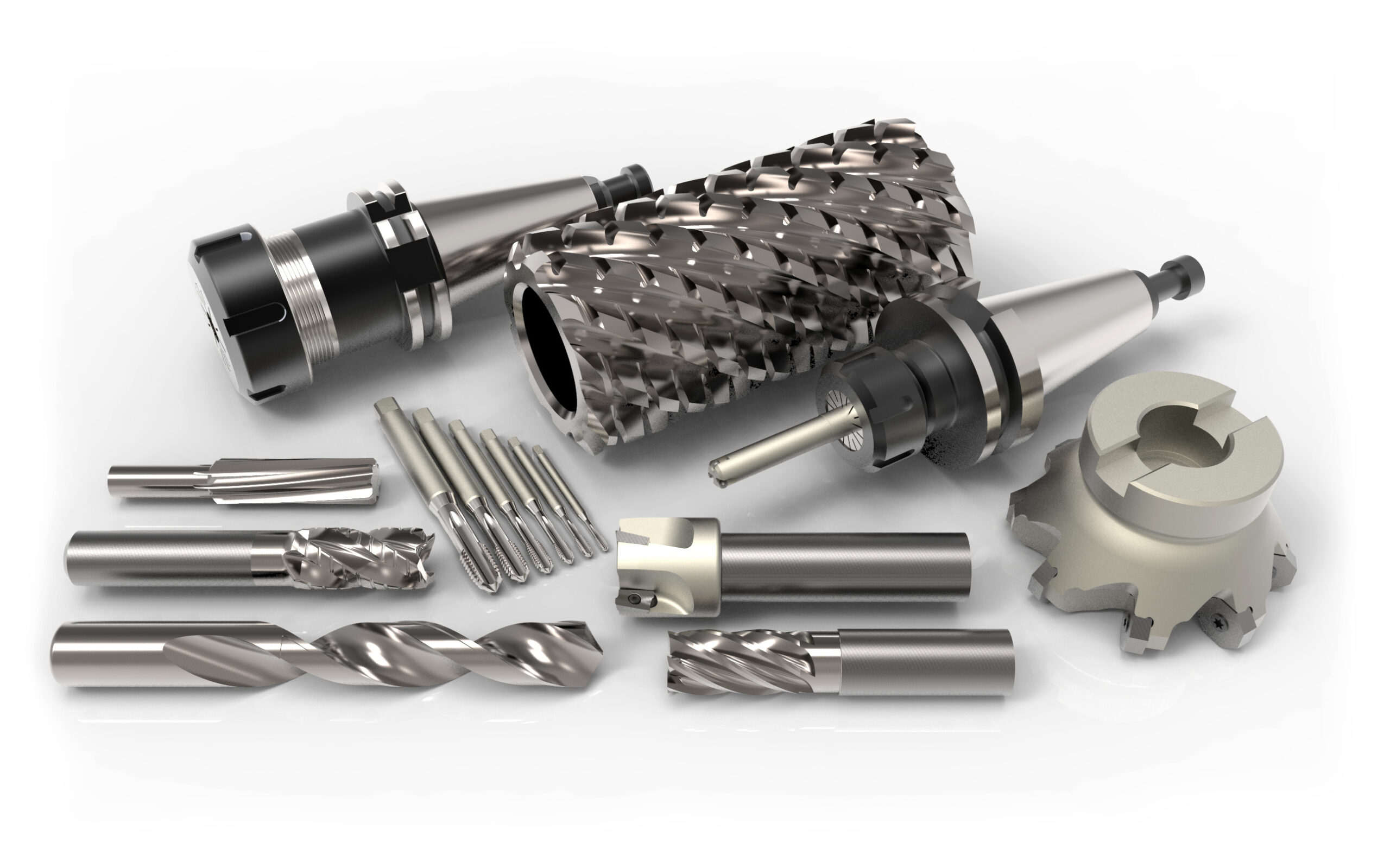

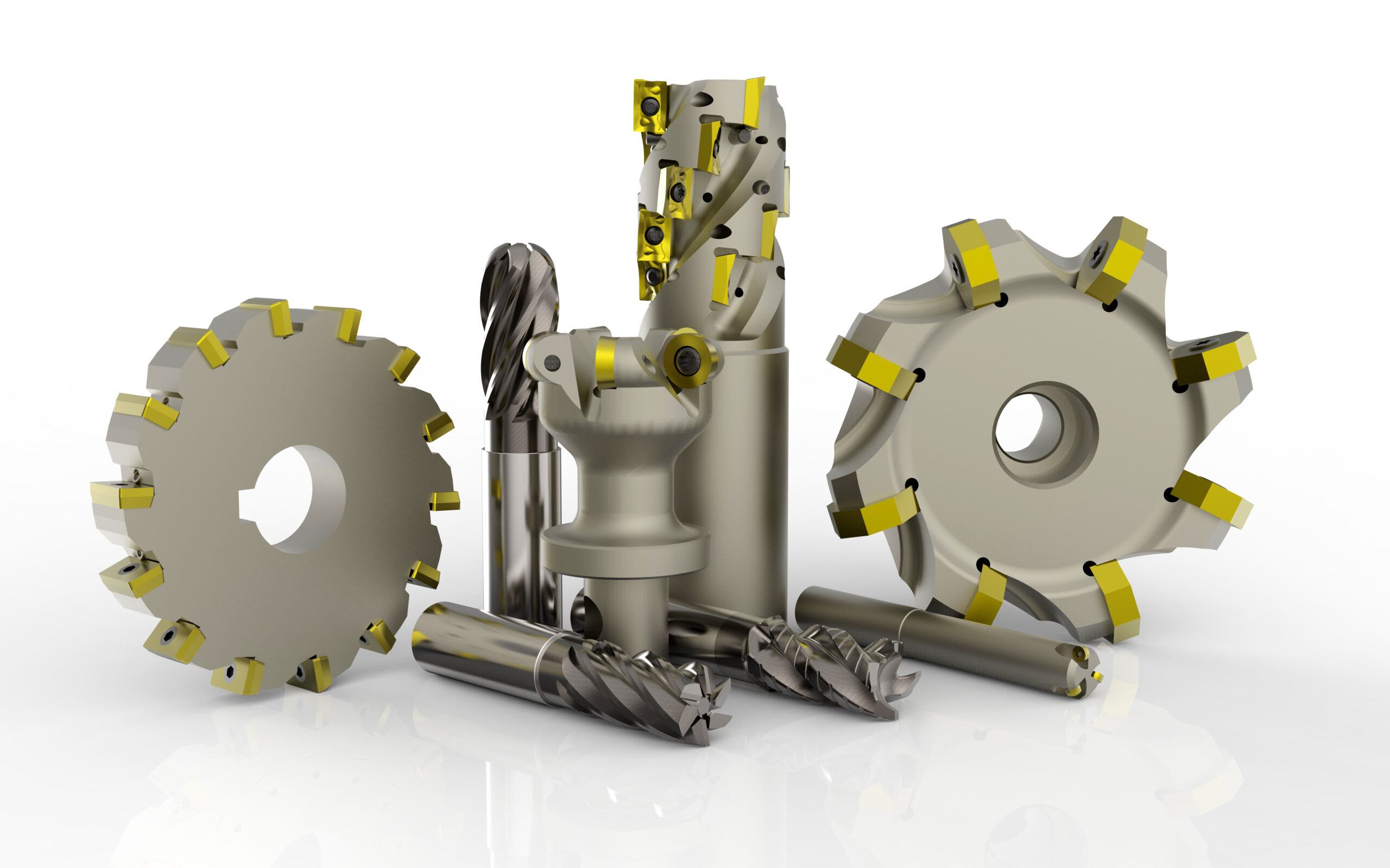

Our in-house precision machining facility is equipped with state-of-the-art CNC machines, tools, consumables and regularly handles complex geometries in tough to machine materials. From intricate aerospace components with tight tolerances to precision machined components for the pharma industry, we specialize in a wide variety of precision machining applications in different industries. Our CNC machining capabilities have enabled us to solve complex challenges and deliver exceptional quality for thousands of components across the globe

Through the use of advanced optimization techniques, we are able to minimize cycle times, reduce tool wear, and optimize material utilization, resulting in cost-effective solutions without compromising on quality or precision. Our commitment to innovation extends beyond the shop floor, as we continuously invest in research and development to stay at the forefront of CNC machining technology